Carrying out a full inspection of the car's body can be a difficult job for car engineers. But with the advent of thermal cameras, this is much simpler and more effective. In this article, we will look into the advantages of using thermal cameras for vehicle checks, such as engine failure, rear windscreen heater line check, vehicle brake pad check, vehicle air-tight check, vehicle exhaust check, and vehicle engine test. Through emphasizing the merits of thermal cameras in those fields, it is hoped that all of you will be aware of the wide application of this technique in car maintenance.

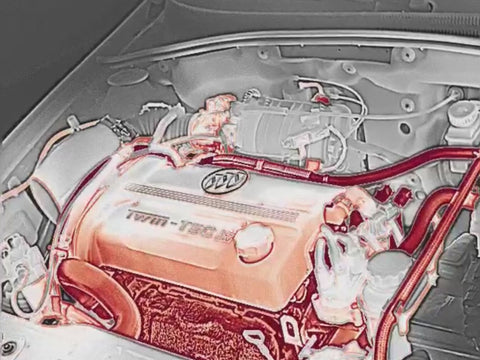

1. Troubleshooting the Engine

The engine is the core of any car, so it's essential to keep it running properly by diagnosing possible problems. Thermal cameras offer a noninvasive way for engineers to detect overheating parts, leakage, and abnormal temperatures in the engine. Through the acquisition of infrared radiation from a variety of engine components, a thermographic camera can quickly and accurately correct the problem, which can lead to high-efficiency maintenance and lower downtime.

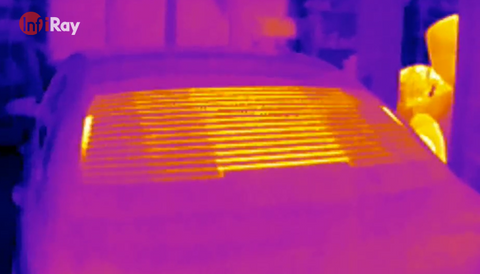

2. Inspection of rear windshield heater wires

The rear windscreen heating line is critical to the thawing of the glass in the cooler months. However, the detection of broken or faulty lines is a tedious process. Thermal cameras allow engineers to detect changes in the heating circuit and to find out if there is a failure or failure in the heating circuit. This guarantees immediate maintenance, resulting in better visibility and more secure operation.

3. Inspection of Automobile Brake Pads

The abrasion of the brake pad is one of the most important problems for the driver because it has a direct impact on the braking capability and security of the vehicle. Conventional testing techniques include dismantling the braking system, which may take time. Thermographic cameras offer a nonintrusive solution by detecting the difference in the temperature of the braking system. By detecting heat or cold areas on a brake pad, engineers can determine the degree of abrasion and make appropriate replacements to improve general security.

4. Inspection of body airtightness

Keeping the car air-tight is essential for a variety of reasons, including the comfort of the occupants, the power of the power supply, and the noise abatement. Thermal cameras can be used to detect air leakage in a vehicle by detecting changes in temperature due to air penetration. This enables engineers to identify and close any gaps or fissures that may result in better-insulating properties, lower power consumption, and increased passenger comfort.

5. Inspection of Automobile Exhaust Pipes

A defective exhaust system can affect the performance of your vehicle, the effectiveness of your fuel usage, and the environment. Thermal cameras allow engineers to spot any problems that may arise in the exhaust system, for example, leakage or blockage, by detecting unusual heat patterns. Quick identification of those issues will allow immediate corrective action to guarantee the optimum performance of the engine as well as the reduction of noxious emissions.

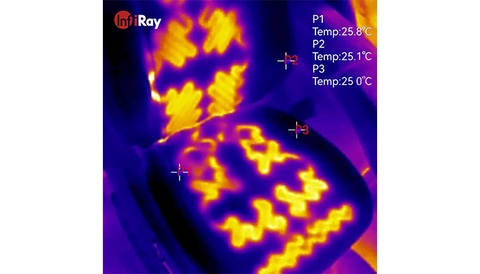

6. Inspection of heated car seats

Through the acquisition of a thermal picture of a sitting area, they can detect a faulty heater or an unbalanced temperature distribution. This enables engineers to rapidly diagnose and correct problems with heated seats, thereby guaranteeing optimum comfort for passengers in frigid weather.

There is no question about the advantages of a thermal camera in car maintenance. Through improvements in efficiency, precision, and security, they have revolutionized the inspection and diagnosis of car problems by engineers. The fact that they are non-invasive and can be used to detect changes in temperature means that they are an essential tool for detecting latent issues and avoiding possible failures. With the continuous development of the automobile sector, adopting the thermographic technique will certainly be the norm, which will result in increased consumer satisfaction and better overall performance. With the help of thermal imaging, car engineers can save time, increase precision, and make more efficient repairs. The time has come for the industry to realize the enormous value of thermal cameras in car maintenance.