Thermographic cameras are a revolution in all sectors, from fire fighting and police to construction inspections and medical diagnosis. Although they are undeniably useful, there is a big problem: Why do thermal cameras cost so much? Let's look at the complexity of this technique and see what's causing it to be expensive.

Understanding Thermal Imaging Technology and Its Application

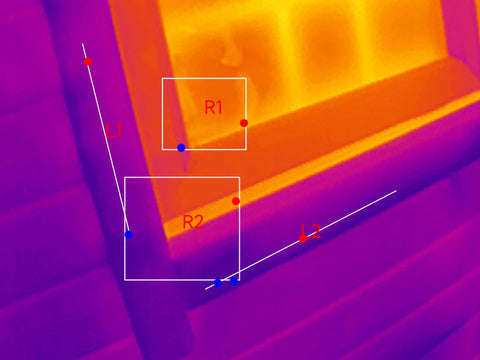

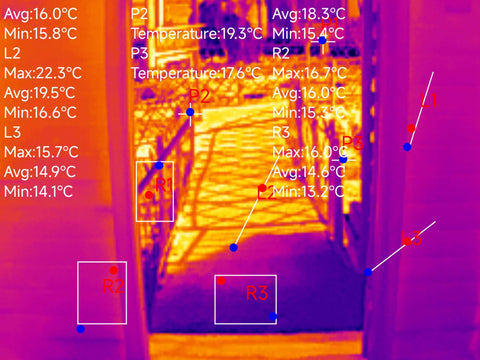

Thermal imaging cameras can measure the infrared emissions of an object and transform it into a visual picture so that the users can observe the temperature changes. The technique is based on sophisticated optical, sensor, and signal processing algorithms to create precise thermal images.

Research & Development Investments

The development of advanced thermal imaging techniques involves significant R&D. Companies are investing in the development of new materials, increased sensor sensitivity, and improved image processing algorithms. Those investments have pushed up the start-up costs of a thermal imaging camera.

Material and Manufacturing Complexity

Precise engineering is critical in the manufacturing of thermal imaging cameras. Strict quality standards require parts to be carefully crafted. The use of materials with excellent thermal conduction properties often increases production costs. Manufacturers must invest in quality control to ensure reliable products.

Regulatory Compliance and Standards

Thermal imaging cameras are required to meet industrial requirements and standards to ensure that they are safe and effective. Obtaining the certificate requires a strict examination and verification process, which results in extra costs for the manufacturer. Nevertheless, compliance with those rules is crucial for instilling trust in customers and regulators.

Industry Dynamics and Market Demand

Demand for thermal imaging cameras has been widely used in different sectors. When demand exceeds supply, producers can take advantage of the momentum of the market to raise their prices. In-line competition also affects pricing policies, with firms trying to distinguish their products according to their characteristics and capabilities.

A Value Proposition for End-user Applications

Although they are expensive, thermostats are of great value for end users. Their ability to detect abnormal events quickly and accurately, improve security in a dangerous environment, and help with preventative repairs to minimize downtime. In assessing the price of a thermal imaging camera, it is important to take into account its long-term performance, security, and cost savings. Of course, as the technique progresses, the price of thermal imaging is steadily declining. Take, for instance, the introduction of a few budget-friendly mobile phone thermal imaging.

The cost of thermal imaging cameras is due to many factors, such as research and development investment, the complexity of production, compliance with regulations, the dynamism of the market, and the value it provides to end users. Although the initial costs might appear expensive, it is essential to acknowledge the long-term benefits and uses of these transformations.