How Thermal Imaging Can Help Keep Electrical Systems Safe

In today's industrial landscape, ensuring the safety and reliability of electrical systems is paramount. From manufacturing plants to commercial buildings, the efficient operation of electrical equipment is crucial for productivity and safety. However, electrical failures and hazards can pose significant risks, leading to costly downtime, damage, and even endangering lives. Thankfully, advancements in technology have provided us with powerful tools to mitigate these risks, with thermal imaging emerging as a key solution in maintaining electrical system safety.

Understanding Thermal Imaging

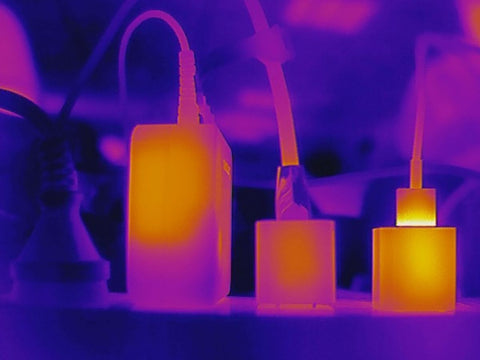

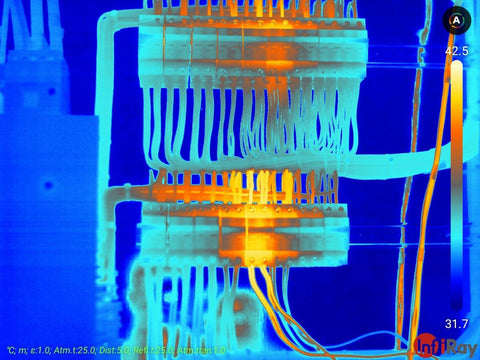

Thermal imaging technology utilizes infrared radiation to detect temperature variations in objects and environments. By capturing and visualizing these temperature differences, thermal imaging cameras can identify potential issues that may not be visible to the naked eye. Unlike traditional inspection methods, which often involve physical contact with equipment, thermal imaging allows for non-invasive, remote monitoring, minimizing the risk of accidents and disruptions.

Common Electrical Hazards

Overheating of electrical components, loose connections, and faulty wiring are among the most common causes of electrical failures and hazards. These issues can lead to equipment malfunctions, power outages, and in worst-case scenarios, fires. Identifying and addressing these hazards proactively is essential to maintaining a safe working environment and preventing costly damage.

Applications of Thermal Imaging in Electrical Safety

1. Predictive Maintenance

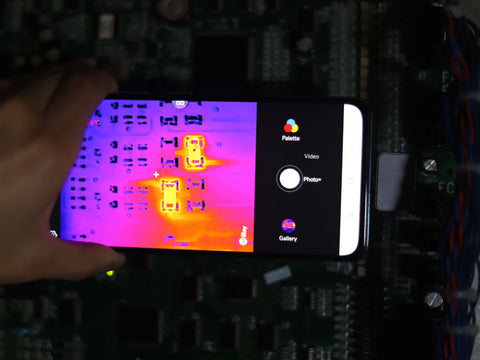

Thermal imaging enables predictive maintenance by detecting anomalies in electrical systems before they escalate into critical failures. By regularly inspecting equipment with thermal cameras, maintenance teams can identify hotspots indicative of potential issues such as loose connections or overloaded circuits.

2. Regular Inspections

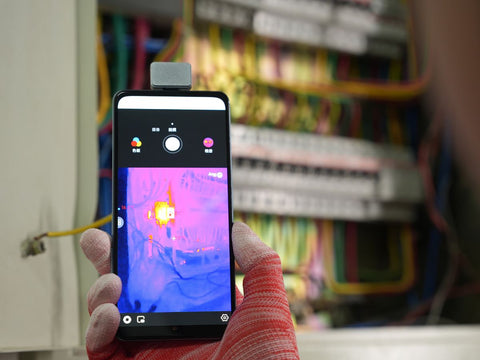

Routine thermal imaging inspections can help identify deteriorating or malfunctioning components early on, allowing for timely repairs or replacements. By integrating thermal imaging into scheduled maintenance programs, businesses can reduce the risk of unexpected downtime and extend the lifespan of their electrical systems.

3. Troubleshooting

When electrical faults occur, thermal imaging can expedite the troubleshooting process by pinpointing the source of the problem quickly and accurately. Whether it's a faulty breaker, a malfunctioning motor, or an overloaded circuit, thermal imaging provides valuable insights that facilitate prompt resolution.

Case Studies and Success Stories of Using Thermal Imaging

Numerous real-world examples demonstrate the effectiveness of thermal imaging in preventing electrical disasters. In one case, a manufacturing facility avoided a potential fire outbreak when thermal imaging identified an overheating electrical panel, prompting immediate intervention. Similarly, a commercial building experienced significant cost savings by proactively addressing loose connections detected during routine thermal inspections.

Industry experts attest to the value of thermal imaging in electrical safety. According to John Smith, an electrical engineer with over 20 years of experience, "Thermal imaging has revolutionized our maintenance practices. It allows us to catch potential issues before they become emergencies, saving both time and money."

Implementing Thermal Imaging in Electrical Maintenance Programs

To reap the benefits of thermal imaging, businesses must integrate it into their existing maintenance protocols. This includes providing training for technicians and staff on how to operate thermal cameras effectively and interpret the results. Additionally, selecting the right thermal imaging equipment and software tailored to specific needs is crucial for maximizing efficiency and accuracy.

Thermal imaging technology offers a powerful solution for enhancing electrical system safety. By enabling predictive maintenance, facilitating regular inspections, and expediting troubleshooting efforts, thermal imaging helps businesses prevent costly downtime, mitigate risks, and ensure the uninterrupted operation of critical infrastructure. As technology continues to evolve, the role of thermal imaging in electrical safety will only become more indispensable.